4 factors should be considered when using sintered stone slabs on cabinet countertops

Release Time : 2021-02-22 View Count : 487 次As we all know, the kitchen is a place for cooking and cooking! A clean and hygienic environment is inevitable! Nowadays, many people choose sintered stone slab to decorate their kitchens, instead of using stone or other materials such as stainless steel. Because sintered stone slabs are excellent materials with strong anti-fouling ability and corrosion resistance.

The creation of the cabinet is the most important thing in the kitchen, and we must pay attention to it . The texture of the sintered stone countertop is clear, layered, and there are many textures. Unlike stone, the texture is very single and there are few choices. The test result of the sintered stone slab is very good. The sintered stone slab has no radiation, is also anti-fouling and anti-scratch. Many advantages are incomparable to those of granite.

Water absorption, density, abrasion resistance, corrosion resistance, compression resistance, hardness, antifouling, acid and alkali resistance, etc., these are the details that the kitchen needs to pay attention to.When using sintered stone in the kitchen, pay attention to these details:

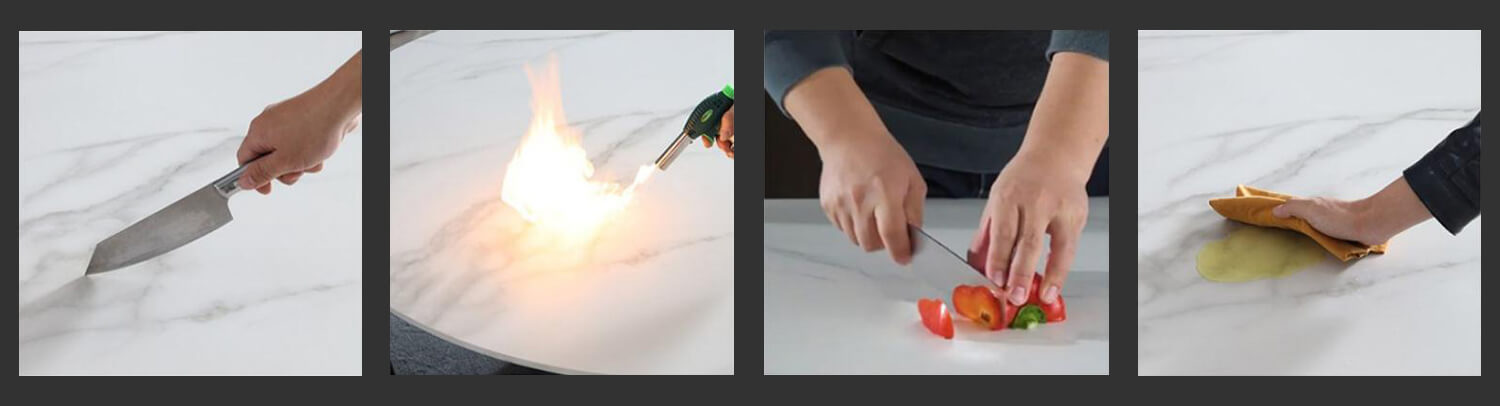

1. Wear-resistant (anti-flowering)

The Mohs hardness of quartz stone countertops is generally 4-5,and the hardness of sintered stone slabs reaches Mohs hardness 6-7, which is not easy to be scratched and worn. Even if it is used in the kitchen with high intensity or is cleaned frequently, it will not leave behind scratches.

2. Heat resistance (lasting without deformation)

The fire rating of the sintered stone is A1, and the frying and frying in the kitchen is nothing to worry about. Because the sintered stone slab is burned at a high temperature of 1250 degrees, the sintered stone is absolutely heat-resistant and high-temperature esistant. It will not deform or release harmful substances when it is directly exposed to high temperature.

3. Acid and alkali resistance (corrosion resistance)

It is known that the water absorption rate of the sintered stone slab is less than 0.01, and there are basically no pores on the surface, so there is no need to worry about water seepage on the sintered stone slab. The slate is resistant to chemicals, solutions, disinfectants, red wine, coffee, olive oil, lemon juice, baking soda, etc., which are commonly found in the kitchen, will not affect the color and gloss of the

surface of the slate.

4.The size is large (one piece is done, do not splice)

Sintered stone countertops are available in large sizes. The size of the sintered stone slab can currently be achieved in multiple sizes such as 2400X1200mm and 3200X1600mm. The processing of large operation surface is larger and more comfortable than cutting board operation space. If you have a small kitchen, one piece is enough to cover the kitchen, and the use of larger slabs means fewer seams, more aesthetics, and less susceptible to dirt.

In summary, sintered stone slabs are currently the best choice for high-end kitchen countertops and the first choice for healthy homes! Kitchen, use a sintered stone, that's right!